Soybean oil is an edible oil extracted from soybeans. As a common crop, soybeans are widely grown all over the world, providing sufficient raw materials for the production of soybean oil. Soybean oil is light yellow to orange-yellow in color, clear and transparent, with a unique bean flavor. It is rich in unsaturated fatty acids (such as linoleic acid and oleic acid), vitamin E and phytosterols, and has the effect of lowering cholesterol and promoting cardiovascular health.

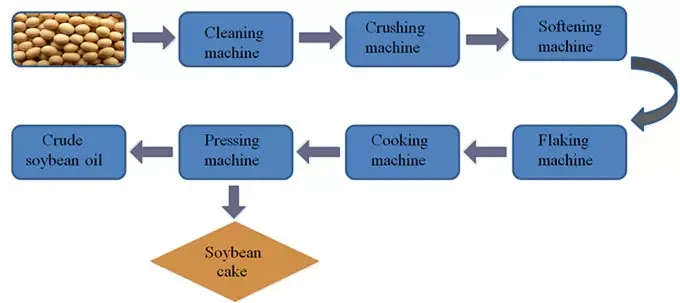

First, the preparation phase of the soybean oil production process begins. This initial phase processes the raw soybeans to make them ready for oil extraction.

1. Cleaning: The soybeans are cleaned to remove impurities. Metallic impurities are removed using a magnetic separator. Non-metallic impurities are removed using sieves and vibrating screens.

2. Crushing: The cleaned soybeans need to be crushed to make the particles smaller and increase the surface area, which is beneficial for subsequent softening, embryo rolling and other processes.

3. Softening: Due to the low oil content of soybeans, softening is usually performed. The crushed soybean particles are conveyed to the softening pot for softening to increase the ductility of the soybeans and make them more suitable for flaking.

4. Flaking : Flaking machine is used to press oil seeds from granules into thin flakes. This process destroys the cell structure of oil seeds and increases the surface area of oil seeds, thereby extracting oil.

5. Steaming cooker: Use a steaming cooker to adjust the temperature and moisture to reach a suitable state for pressing.

6. Pressing: The steamed and fried cooked dough is transported to the soybean oil press for pressing to obtain soybean crude oil.

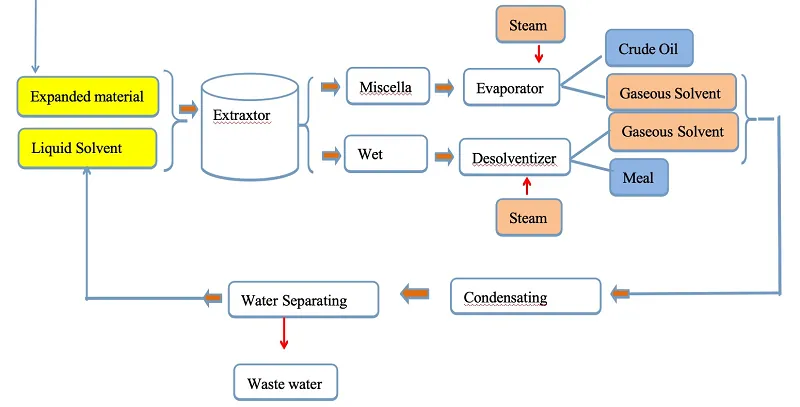

Soybean oil solvent extraction is a modern oil production method that uses organic solvents (usually n-hexane) to extract oil from soybeans. Compared with the traditional pressing process, the extraction process has the advantages of high oil yield, low residual oil rate in the meal, low labor intensity, high production efficiency, and easy large-scale continuous production. It is currently a widely used process in soybean oil production.

Solvent extraction: The oil solvent extraction process adopts the principle of solid-liquid extraction, adding solvent (n-hexane) to oil-producing soybean germ to dissolve it in the solvent to form a mixed oil. (Extraction machine: horizontal rotary extraction machine, ring extraction machine, drag chain extraction machine)

Wet meal desolventizing: The wet meal after leaching contains a certain amount of solvent, which needs to be removed through the desolventizing process. The principle of desolventizing is to use high-temperature steam to vaporize the solvent in the wet meal and extract the solvent vapor through a vacuum system. (Desolventizing equipment: desolventizer)

Mixed oil treatment: After the mixed oil is left to stand, the solvent and oil are separated by evaporation, stripping and other processes based on the principle of different boiling points between the solvent and the oil to obtain crude oil. The crude oil is transported to the refining equipment for refining treatment to remove impurities and improve the purity and stability of the oil.

Solvent recovery process: The solvent is evaporated and separated by steam stripping in the evaporator. The separated solvent enters the condenser for condensation after steam stripping. The condensate enters the water separation tank for water separation. The separated solvent returns to the solvent turnover warehouse for continuous recycling.

1. Degumming: Degumming is the first step in soybean oil refining to remove phospholipids. The commonly used degumming method is hydration degumming, that is, adding a certain amount of hot water or dilute alkaline solution to the crude oil to make phospholipids and other colloids absorb water, expand and condense, and then separate the colloids from the oil by centrifugation.

2. Deacidification: Deacidification is the removal of free fatty acids in crude oil. Alkali refining is generally used. An appropriate amount of alkaline solution is added to the crude oil to neutralize the free fatty acids with the alkali to produce soap and glycerin, and then the soap and oil are separated by centrifugation.

3. Decolorization: Decolorization is to remove the pigment in the oil and improve the color and transparency of the oil. The commonly used decolorizer is activated clay. Activated clay is added to the deacidified oil, stirred and adsorbed under certain temperature and vacuum conditions, so that the pigment is adsorbed on the surface of the clay, and then the clay is separated from the oil by filtration.

4. Deodorization: Deodorization is the process of removing odorous substances from oils and fats. Deodorization is achieved by passing steam directly into the oils and fats under high temperature and high vacuum conditions, so that the odorous substances evaporate along with the steam.

If you have any needs for soybean oil production line, soybean oil processing equipment or technology, please feel free to contact us. We will provide you with professional soybean oil extraction solutions to help you efficiently produce high-quality edible oil!