Sunflower oil is a common vegetable oil extracted from sunflower seeds. We offer complete sunflower oil production lines with capacities ranging from 10 tons/day to 3,000 tons/day. Sunflower oil production lines include cleaning, shelling, shell-kernel separation, flaking, pressing, filtering, extraction, refining and packaging. Some steps can be customized according to specific needs, providing fully automatic or semi-automatic solutions to meet the needs of different budget levels.

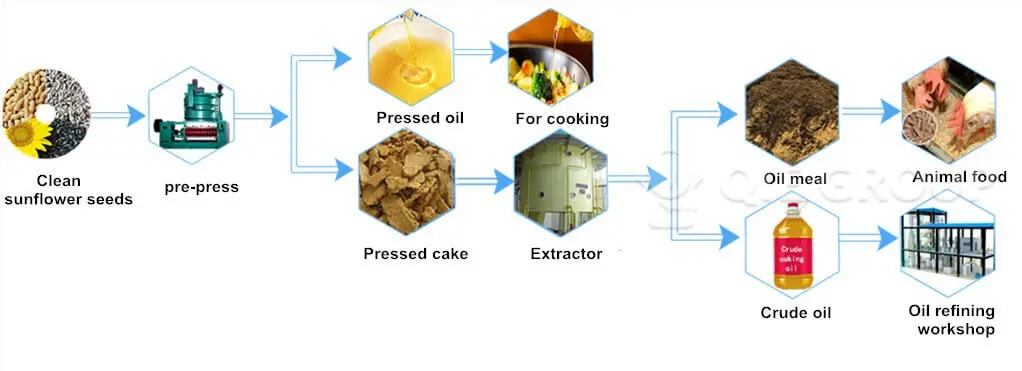

The sunflower oil extraction method can also be customized according to the capacity of the sunflower oil mill. For mills with a capacity of less than 50 tons/day, a mechanical screw press is feasible. For mills with a capacity of more than 50 tons/day, solvent extraction is usually used in conjunction with a mechanical press. Sunflower oil mills are also suitable for the extraction of other plant seeds and nuts, such as peanuts and rapeseed.

The raw materials of sunflower seeds need to go through the processes of cleaning, shelling, kernel-shell separation, and flaking:

Impurities, stones and metal objects are removed through vibrating screens, stone removers and magnetic separators to avoid equipment wear and oil pollution. Double roller shelling machines and air separation equipment are used to completely separate the sunflower seed shells from the kernels, with the kernel shell content less than 1%, reducing energy consumption and impurities in subsequent processes. The sunflower seed kernels are pressed into thin slices to destroy the cell structure and improve the efficiency of oil release.

Physical pressing process: using double-screw sunflower seed oil press, through three-stage pressing to achieve efficient oil output. The pressing temperature is controlled at 60-70℃, retaining more natural nutrients, suitable for the production of cold-pressed sunflower seed oil.

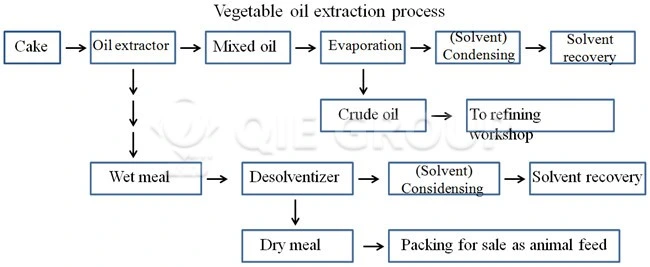

Solvent extraction process: The pressed cake is extracted twice using n-hexane solvent, and the oil yield can reach more than 98%. The extracted crude oil needs to be recycled through a desolventizing tower, and the residue is removed through a refining process.

The refining process includes degumming, alkali refining, decolorization, deodorization, etc. Degumming: removes phospholipids and other gum components through hydration to prevent oil oxidation and precipitation.

Alkali refining: Use sodium hydroxide to neutralize free fatty acids, generate soap stock and precipitate and separate it to reduce the acid value.

Decolorization: Add activated white clay and diatomaceous earth to absorb pigments and impurities in a vacuum environment to improve the transparency of oil products.

Deodorization: Under high temperature and vacuum conditions at 250-260℃, odorous substances are removed through steam distillation to ensure the pure flavor of the oil.

Dewaxing: Remove the wax components in sunflower oil through low-temperature crystallization and filtration technology to ensure that the product remains clear and transparent below 5°C.

If you are interested in starting a sunflower oil production line business or want to know more detailed information about sunflower oil press and refining, please feel free to contact us, we will serve you with sincerity and patience!