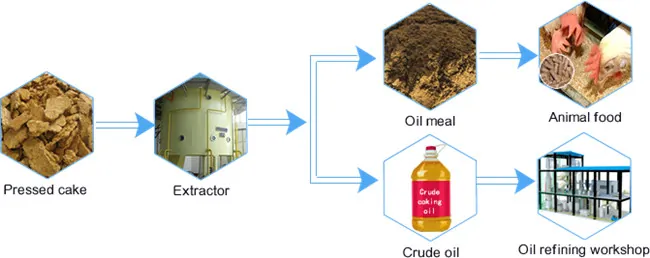

In the field of edible oil processing, edible oil solvent extraction plant plays a vital role. It is the second process of edible oil processing. The cake from the edible oil pressing section (i.e. the product after the pressing process) will be transported to the extraction equipment. These cakes still contain a lot of oil, and the main task of the edible oil solvent extraction plant is to fully extract the residual oil using chemical extraction technology.

The process of edible oil solvent extraction plant is rigorous and efficient. First, the pre-pressed cake is sent to the solvent extraction equipment, and then the cake is soaked or sprayed with a specific organic solvent. The core principle is to use the difference in the solubility of the solvent to the oil to make the solvent fully contact with the cake and dissolve the oil in the cake. After that, after a series of complex separation and refining processes, pure edible oil is finally obtained. The whole process cleverly uses chemical principles to ensure efficient extraction of oil.

The edible oil solvent extraction plant has a wide range of applications. For materials with high oil content such as sesame, pre-pressing and extraction can be performed. After sesame pre-pressing, the extraction equipment can further extract the remaining oil in the cake to increase the oil yield. For materials with low oil content such as soybeans, after squeezing out the cake, the solvent extraction equipment can perform secondary extraction on the cake to fully tap the oil value of the material and maximize resource utilization.

1. High oil yield and significant economic benefits : Edible oil extraction equipment adopts advanced technology and design, which can extract oil from cake to the maximum extent, and the oil yield is much higher than that of traditional equipment. This enables enterprises to obtain more edible oil products with the same raw material input, thereby significantly improving economic benefits.

2. Low residual oil rate of dry meal and cake : The residual oil rate of dry meal and cake after being treated by leaching equipment is extremely low, which not only improves the oil extraction efficiency, but also the cake can be reused as high-quality feed raw materials or other industrial raw materials, further improving the added value of the product.

3. Low consumption and high output : The design of this equipment fully considers the conservation of energy and raw materials. During operation, while maintaining efficient production speed, it effectively reduces energy consumption and solvent consumption, meeting the requirements of modern industrial energy conservation, emission reduction and efficient production.

4. High degree of automation : The edible oil extraction equipment adopts an advanced automatic control system to realize the automation of the entire process from feeding, extraction, separation to discharging, which not only reduces manual intervention and labor intensity, but also improves production stability and consistency of product quality.

5. Latest design, excellent quality, professional installation team : The equipment adopts the latest design concepts and technologies, strictly controls the selection of materials and manufacturing processes to ensure the excellent quality of the equipment. At the same time, the professional installation team can provide users with a full range of installation and commissioning services to ensure that the equipment is put into production quickly and stably.

In summary, edible oil solvent extraction technology has become one of the most advanced production technologies in the international edible oil processing field due to its significant competitive advantages in structure and utilization rate. Edible oil extraction equipment has brought great changes and development opportunities to the edible oil processing industry in terms of process flow, use and characteristics.