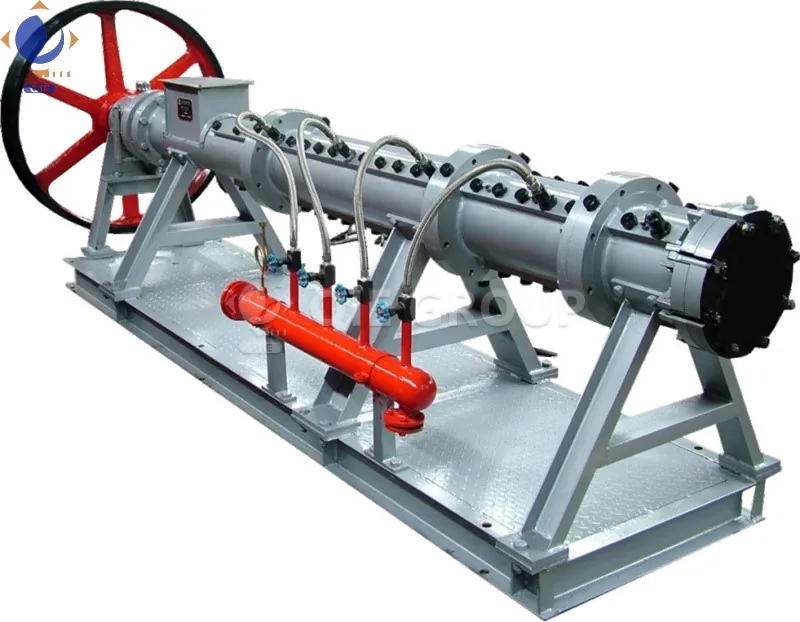

Oil puffing machine is a process that uses extrusion equipment to convert crushed, crushed or whole oil into porous expanded particles. It is widely used in the pretreatment of soybean, rapeseed, cottonseed, rice bran and other oils. The expanded material can improve the leaching efficiency, reduce the loss rate of solvent and steam, improve the quality after leaching, shape the material particles, and is more conducive to the extraction of crude oil.

1. Improve the output of the extractor: After the oil is extruded and expanded, the bulk density of the expanded particles increases, the oil cell tissue is completely destroyed, the internal porosity increases, the free oil on the surface increases, the particle size and mechanical strength increase, the permeability of the solvent to the material layer is greatly improved during leaching, the leaching rate is improved, the oil preparation and processing technology is improved, and the leaching time is shortened, so the output of the extractor can be increased by 30% to 50%.

2. Improve the output of wet meal desolventizing equipment: When the expanded particles are extracting oil, the permeability of the solvent to the material layer is improved, so that the solvent content of the wet meal after extraction is only 60% of the solvent content of the raw particles after extraction (the solvent content of the wet meal is reduced from 30% to 20%), which can not only improve the output of the wet meal desolventizing equipment, but also greatly reduce the energy consumption required for wet meal desolventizing.

3. Increase the concentration of mixed oil, thereby reducing the evaporation load of mixed oil. The solvent content of expanded pellets during leaching is about 40% lower than that of raw pellets, about 0.65:1, so that the concentration of mixed oil after leaching can reach 30% to 35%, greatly saving the energy consumption of mixed oil evaporation. In addition, the powder content in the mixed oil is reduced, which reduces the purification load of the mixed oil, improves the evaporation effect of the mixed oil, and improves the quality of the leached crude oil. Since the solvent content in the wet meal is reduced and the concentration of the mixed oil is increased, the solvent loss in the leaching production is significantly reduced.

4. After puffing, the enzymes in the oil are passivated, which improves the quality of the oil. Since the puffing process passivates the lipoxygenase, phospholipase and other enzymes in the oil, the acid value of the crude oil is reduced, the non-hydratable phospholipid content is reduced, and the quality of the crude oil is improved. At the same time, the passivation of enzymes during the puffing process also basically removes the bitterness of soybean meal, improves palatability, and improves quality.

If you are interested in oilseed puffing machine, or need to know about the complete set of process equipment for oilseed pretreatment (such as cleaning equipment, crushers, flaking machine, setam cooker,solvent extraction equipment, etc.), please feel free to contact us!