In the global vegetable oil market, cottonseed oil content is 15% to 25%, cottonseed kernel oil content is 32% to 46%, and protein content is 30%, making it an important source of edible oil and vegetable protein. The content of unsaturated fatty acids (linoleic acid and oleic acid) in cottonseed oil is as high as 60% to 90%, which has the effect of lowering cholesterol and preventing arteriosclerosis, and is also an important edible vegetable oil.

Cleaning - shelling - flaking - steaming - pressing - solvent extraction

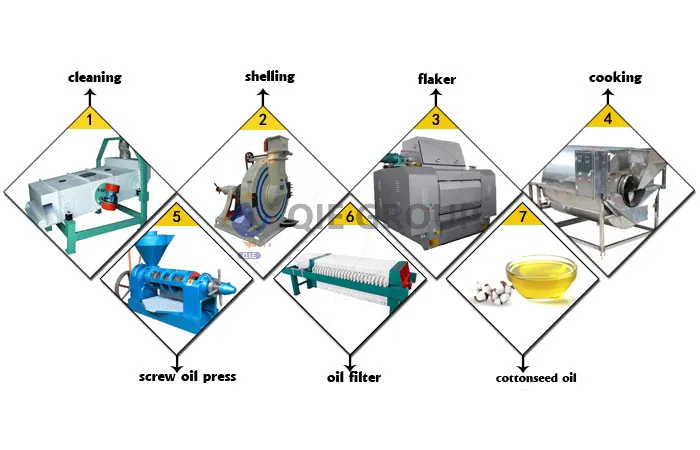

Cottonseed cleaning : Cleaning refers to the use of cottonseed cleaning equipment to remove various impurities in cottonseed. Cleaning cottonseed can reduce oil loss, increase oil yield, improve the quality of oil, cake and by-products, reduce equipment wear, improve processing capacity and improve the working environment.

Cottonseed hulling :Cottonseed hulls contain brown pigments, pesticide residues, wax and lint. Hulling can improve the processing capacity of the oil press, increase the oil yield, and improve the quality of crude oil and meal. Cottonseed hulls can be used for mushroom cultivation, as livestock feed, etc.

Flaking : The flaking process rolls cotton seeds into thin flakes, destroys the cell walls, and greatly shortens the oil output path, thereby increasing the oil output speed and rate.

Steaming :This process is to heat and cook the rapeseed, which is easy to separate the oil and can provide sufficient oil for the pre-pressing machine. This process is easy to operate and has a long service life.

Cottonseed pre-pressing: Pressing is the process of pressing cottonseed kernels into thin flakes to increase the surface area of the oil, destroy its cell structure, shorten the oil output path, and speed up the oil output.

Pre-pressed cake - cottonseed extraction - wet meal desolventization - mixed oil evaporation - solvent condensation recovery - crude cottonseed oil - refining workshop

Cottonseed oil extraction process: first, the cottonseed cake is contacted with the solvent to make the oil in the cake and the solvent fuse to form a mixed oil. After the mixed oil is evaporated and stripped by the mixed oil treatment system, the solvent is vaporized and discharged to obtain crude cottonseed oil.

Solvent extraction can achieve high oil yield. Large-capacity extractor design, large processing capacity, high efficiency and low cost. Unique solvent vapor recovery system to keep the production environment clean and efficient. Energy recycling and low energy consumption.

1. Cottonseed oil hydration degumming : In crude oil, colloidal impurities are mainly phosphorus. The presence of colloidal substances such as phospholipids will reduce the quality of the oil. In addition, during the alkali refining and deacidification process, they will cause excessive emulsification of oil and alkali, making saponification separation difficult, thereby increasing the loss of neutral oil, so they must be thoroughly removed in advance.

2. Cottonseed oil deacidification : The core task of oil deacidification is to remove free fatty acids in crude oil, as well as a small amount of colloids, pigments and trace metal substances in the oil. The quality of deacidification operation directly affects the oil yield and quality of oil refining, and is one of the key factors. In industrial production, alkali refining deacidification is the most widely used method.

3. Cottonseed oil decolorization : The color and some impurities of the oil can meet the product quality standards after decolorization. Moreover, decolorization can also create more favorable conditions for the subsequent deodorization and refining processes. Decolorization needs to achieve the following goals: make the product color meet the final requirements; remove related pigments and trace metals; further remove the trace saponins, phospholipids and other colloidal impurities and certain odor substances remaining in the oil; eliminate polycyclic aromatic hydrocarbons and residual pesticides; reduce the peroxide value of the oil.

4. Cottonseed oil deodorization: The main purpose of oil deodorization is to remove odor-causing substances and other volatile substances in the oil, thereby improving the smell and color of the oil and enhancing the stability of the oil. The unique smell of the oil itself, the odor generated during the decolorization process, and the clam smell generated by oil oxidation are all substances that need to be removed. In the deodorization stage, it is necessary to use vacuum high temperature to directly inject steam for distillation to completely remove these unpleasant odors.

1. Adopt QIE Group's most advanced automation and intelligent control technology to monitor the entire production process to ensure product stability and production line efficiency.

2. The efficient integration of technology and automation effectively reduces customer labor input and improves product indicators and stability.

As a cottonseed oil production line manufacturer, we always pay attention to customer needs and provide customers with efficient, low-cost, high value-added solutions through process optimization, intelligent control and energy-saving and environmental protection technologies. Whether it is the full industrial chain layout of large grain and oil enterprises or the capacity upgrade of small and medium-sized oil mill plant, we can provide customized services.