The oil content of rice bran itself is relatively low, but this rice bran oil solvent extraction equipment can control the residual oil rate below 1% with its advanced technology , greatly improving the oil extraction efficiency.

If you intend to establish a rice bran oil solvent extraction production line, obtaining sufficient rice bran raw materials is the first priority, and purchasing from rice mills is a good way. It is worth noting that the oil content of rice bran is in the range of 15-20%, which means that rice bran contains considerable oil resources. Rice bran oil solvent extraction equipment is a powerful tool to help you fully tap this resource and extract more oil from rice bran.

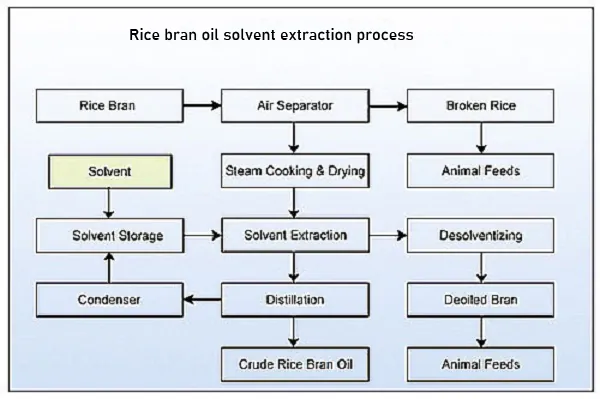

However, before the rice bran oil solvent extraction equipment extracts rice bran oil, pretreatment of rice bran is an essential step, and the rice bran pretreatment puffing method is a more commonly used method. The rice bran oil solvent extraction process mainly covers four key parts: solvent extraction system, DTDC system, mixed oil treatment system, and condenser and recovery system. The following is a detailed introduction to the work flow of each part:

1. Solvent extraction : In the extractor, the treated rice bran is soaked or sprayed with an organic solvent (n-hexane) to dissolve the oil. Finally, two parts are obtained: one is a mixture of solvent and rice bran oil, called mixed oil; the other is a mixture of solvent and rice bran meal, called wet meal.

2. Mixed oil treatment : Based on the difference in boiling points of different substances, the mixed oil is evaporated and stripped. In this process, the solvent evaporates into steam and separates from the oil. The pure rice bran crude oil is pumped into the oil tank, and the solvent is recycled and reused in the last process - the solvent recovery section.

3. Solvent recovery : This section is used to recover solvents from the mixed oil processing section and the wet meal DTDC system and use them for the next round of production. Solvent vapor can be recycled through scientific means such as condensation and cooling, which not only saves costs but also meets environmental protection requirements.

4. Meal processing : A small amount of solvent will remain in the meal, which will be dried after desolventizing and drying. In this process, the solvent will also evaporate into steam, which can also be recycled through condensation, cooling, etc.

If you are very interested in rice bran oil solvent extraction technology. Or do you want to start a rice bran oil production business? Tell us your needs, our engineers can design a technical solution for you, and QIE 's project manager can provide you with professional rice bran oil production business advice.