In the production process of peanut oil factory, peanut oil solvent extraction equipment is one of the core equipment and plays a pivotal role. This equipment has excellent performance and can efficiently extract and produce peanut oil from various oil cakes. It is applicable to a wide variety of oil crops, including not only peanuts, but also soybeans, sesame, coconut, flax seeds, sunflower seeds, castor seeds, cotton seeds, palm kernels, etc.

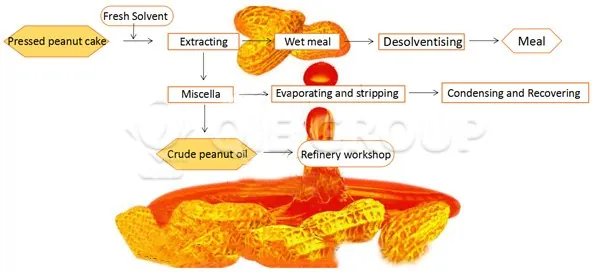

The peanut oil solvent extraction plant is a complex system, which is mainly composed of extraction system, DTDC system, condensation system and recovery system. These systems work together to complete the extraction of peanut oil. In order to meet the diverse needs of different customers, we provide peanut oil extraction equipment of various specifications. Whether you are a small workshop or a large production enterprise, you can find the equipment suitable for you.

Our peanut oil solvent extraction plant uses the most scientific oil extraction method and focuses on extracting crude peanut oil from peanut meal. Its advanced peanut oil extraction process is uniquely designed to achieve high-yield peanut edible oil extraction with low solvent addition, which not only reduces production costs but also improves production efficiency.

Solvent extraction: Solvent extraction is a process of extracting oil from cake using solvent. In actual operation, 6# leaching solvent oil or commercially available hexane is generally used as solvent. The oil is dissolved from the cake through full contact between the solvent and the cake.

Desolventization: The desolventization process mainly removes and recovers the solvent in the meal, and dries and cools the meal at the same time. This process not only reduces the waste of solvent, but also ensures the quality of the meal, making it meet the requirements of subsequent processing or use.

Evaporative stripping: The evaporative stripping process uses indirect steam to heat the mixed oil, evaporate the solvent, and concentrate the mixed oil. Through this process, the oil concentration in the mixed oil can be further increased to prepare for subsequent oil extraction.

Solvent recovery: Solvent recovery is very important. It can effectively recover solvents and reduce solvent consumption. Solvent recovery can not only ensure the safe production of peanut oil extraction equipment and avoid safety accidents caused by solvent residues, but also improve product quality and reduce the impact of impurities on the quality of peanut oil.

1. Pretreatment and extraction : The pretreated material is sent to the rotary press by a scraper conveyor. In the rotary press, the material is fully contacted with the solvent or mixed oil for extraction. After this step, the material is separated into two parts: meal and mixed oil.

2. Desolventization and solvent recovery of meal : The meal is sent to the roaster, where the solvent in the meal is separated. The separated solvent enters the condenser and returns to the rotary pressing device after condensation, thus realizing the recycling of the solvent.

3. Preliminary separation of mixed oil : The mixed oil produced by the rotary pressing device enters the first evaporator and the second evaporator. In the evaporator, most of the solvent in the mixed oil is separated and the concentration of the mixed oil is further increased.

4. Deep separation of mixed oil and solvent recovery : The mixed oil produced by the second evaporator enters the stripping tower, where almost all the solvent is separated. From the stripping tower, we get crude oil and solvent. The solvent is also sent to the condenser, and after condensation, it returns to the rotary press and participates in the production cycle again.

In summary, the peanut oil solvent extraction plant has an irreplaceable position in the peanut oil pressing industry. Its scientific process design, reasonable equipment composition and efficient working principle make it play a huge role in peanut oil production. Whether from the applicability of the equipment, the advancement of the process or the safety of production, the peanut oil extraction equipment is an ideal choice for the peanut oil pressing plant. QIE GROUP can also tailor solvent extraction solutions according to user needs to meet the specific needs of different users.