In soybean oil production, many people only focus on pressing efficiency. However, the key step that truly determines oil yield and quality is often overlooked – the solvent extraction process. Don't underestimate this step; it directly impacts the quality of the final oil, energy consumption, and overall cost. A properly optimized extraction system can yield an extra 1-2 kilograms of oil per ton of soybeans, resulting in a difference in profits of hundreds of thousands or even millions of yuan per year. 👉 Further Reading: [ Which is more profitable, solvent extraction or pressing for soybean oil? ]

Under traditional processes, many oil plants still use old-fashioned solvent leaching tanks, relying on manual experience to control solvent concentration and temperature. This not only results in large fluctuations and poor stability, but also frequently causes safety hazards due to improper operation.

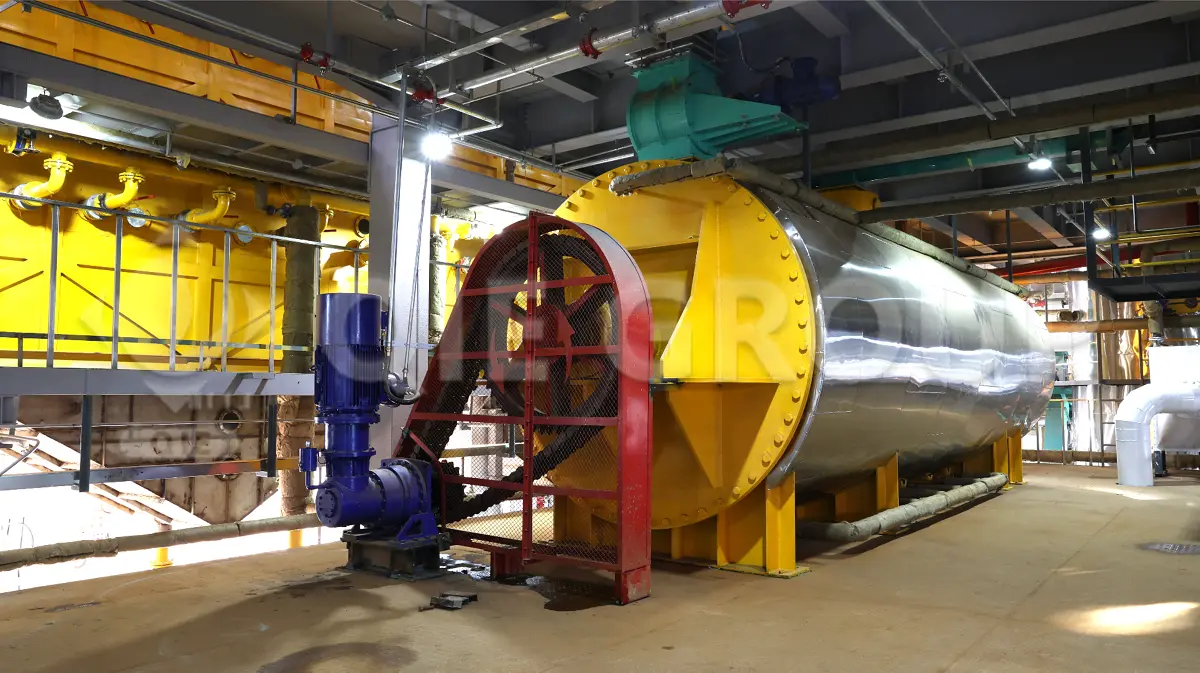

Professional suppliers like QIE Group have long incorporated intelligent and energy-saving concepts into their designs. They don't simply replace equipment; they redefine the logic of the entire leaching process: from material flow and heat recovery to safety protection, every detail has been repeatedly verified.

Traditional solvent extraction equipment often suffers from drawbacks such as complex operation, high energy consumption, and difficult maintenance. Our fully automatic soybean oil solvent extraction equipment, through a PLC intelligent control system and a central monitoring platform, achieves full automation of the entire process from feeding, solvent extraction, desolventizing, evaporation to solvent recovery.

1️⃣ The interface is available in both Chinese and English , supporting multilingual switching for the convenience of international users;

2️⃣ Local control buttons and automatic interlocking procedures ensure operational safety;

3️⃣ Automatic alarm and trend recording system for real-time monitoring of operational status;

4️⃣ Two operators can complete the entire production line , significantly reducing labor costs.

This system greatly simplifies the process while maintaining high equipment stability and high oil yield. 👉 Further Reading: [ How to Improve Soybean Oil Extraction Rate? ]

We are well aware of the demands that continuous production places on equipment durability and maintainability. Therefore, we have comprehensively optimized the details of the mechanical structure:

1️⃣ External bearing design avoids solvent corrosion and extends service life;

2️⃣ The scraper chain has been upgraded for wear resistance , ensuring smooth material conveying;

3️⃣ Hardened gear reducer and quick-opening hand hole structure make maintenance faster;

4️⃣ The lifting lug structure facilitates the hoisting and replacement of large components;

5️⃣ Leak-proof sealing system to ensure workshop safety and solvent recovery rate.

These improvements make the equipment more stable in long-term operation, extend maintenance cycles, and significantly reduce unexpected downtime.

With rising energy prices and increasingly stringent environmental policies, energy conservation and emission reduction have become crucial for oil refineries' competitiveness. Our intelligent solvent leaching system is based on "low feed-to-solvent ratio, high-efficiency mass transfer, negative pressure evaporation, and waste heat recovery."

1️⃣ Low solvent ratio process : Reduces solvent usage while maintaining oil yield;

2️⃣ Multi-stage negative pressure evaporation system : significantly reduces steam consumption;

3️⃣ Oil-to-oil and solvent heat exchange design : recovering and reusing waste heat;

4️⃣ Solvent recycling and purification system : Improves recovery rate and reduces emission risks.

In practical applications, the system's overall energy-saving rate can reach 15%–20%, which not only reduces operating costs but also meets international environmental protection standards.

QIE Group's intelligent solvent leaching equipment has been successfully operating in several countries, including Egypt, Indonesia, Nigeria, and Uzbekistan.

For example, in the 30-ton/day soybean oil production line project in Egypt, through the low material-to-solvent ratio design and multi-stage heat recovery system, the oil plant's overall energy consumption was reduced by about 18% compared to traditional solvent leaching equipment, solvent consumption was reduced by nearly 20%, and the equipment uptime exceeded 95%.

Similar results have been validated in many parts of Southeast Asia and Africa, providing replicable smart energy-saving solutions for oil plants worldwide.

Safety is always the top priority in the design of QIE Group's equipment. The system is equipped with multiple protection and automatic monitoring modules:

1️⃣ Overload protection and shaft monitoring device

2️⃣ Combustible Gas Detection and Alarm System

3️⃣ Emergency Interlock and Automatic Shutdown Procedures

4️⃣ High Temperature and Pressure Multi-point Sensing System

These intelligent protections ensure that the equipment can continue to produce stably in a safe and controlled environment, even under high load.

Q1: What raw materials are suitable for your soybean oil solvent extraction equipment?

A: It can be widely used for oil-containing raw materials such as soybeans, rapeseed, sunflower seeds, cottonseed, and rice bran. The system can adjust parameters according to the characteristics of different oilseeds.

Q2: Can the system be customized according to local standards and climate?

A: Yes. QIE Group supports customized designs based on the voltage, humidity, solvent type, and environmental standards of different countries.

Q3: What are the advantages of this leaching system in terms of energy consumption compared to traditional equipment?

A: Through multi-stage heat recovery and low material-to-solvent ratio design, the overall energy consumption can be reduced by 15%–20%, significantly reducing steam and solvent consumption.

Q4: What is the oil yield of the equipment?

A: Under standard raw material conditions, the oil yield of soybeans can reach 18.5%–19%, which is about 2 percentage points higher than that of conventional equipment.

Q5: Does QIE Group provide installation and training services?

A: Yes. We provide global installation, commissioning, operation training, and technical guidance to ensure our customers can successfully launch production.

Q6: What are the system maintenance cycles and after-sales support?

A: The equipment is made of highly wear-resistant materials and can be inspected every 6-8 months under normal operation. We provide 24/7 remote technical support and spare parts supply services.

If you're also facing issues like unstable oil yield, high energy consumption, or frequent equipment malfunctions, consider starting with the solvent extraction process. This isn't just a simple equipment upgrade; it's a complete restructuring of the entire production logic. Don't let a single drop of soybean oil go to waste; let technology truly serve efficiency.

If you are looking for reliable, intelligent, and sustainable soybean oil production line solutions, QIE Group, with over 40 years of experience in oleochemical engineering, can provide you with customized solvent extraction system design and implementation support.

Contact us now for details on solvent leaching equipment.