Are you planning to build an edible oil processing plant, but worried about the complex equipment selection, tedious installation, and unfamiliar processes ? Many investors encounter these problems in the early stages of plant construction: unclear budgets, difficult process control, and inappropriate equipment combinations.

Leveraging over 40 years of experience in grain and oil machinery manufacturing and engineering, We has successfully provided complete edible oil processing plant equipment and solutions to clients in over 100 countries worldwide. Whether your project is a small oil mill or a large, fully automated production line, we offer customized solutions tailored to your production capacity goals and investment budget, helping you quickly achieve operational success and stable profitability.

Including cleaning screen, stone remover, shelling machine , crusher, flaking machine , steam cooker , etc.

Ensure that the raw materials are clean and have appropriate moisture content, laying the foundation for subsequent pressing or leaching

Mechanical pressing, suitable for high-end healthy edible oil

High oil yield, easy operation, and can handle a variety of oils

Solvent extraction process, suitable for large-scale production

The oil yield is extremely high, which can maximize the utilization of raw materials

Degumming, deacidification, decolorization, deodorization, dewaxing

Improve oil transparency and stability

Ensure that finished oil products meet international food safety standards

Provide process flow chart and equipment layout diagram

Workshop power and automation control system planning

Completely solve the problem of connecting factory layout and production process

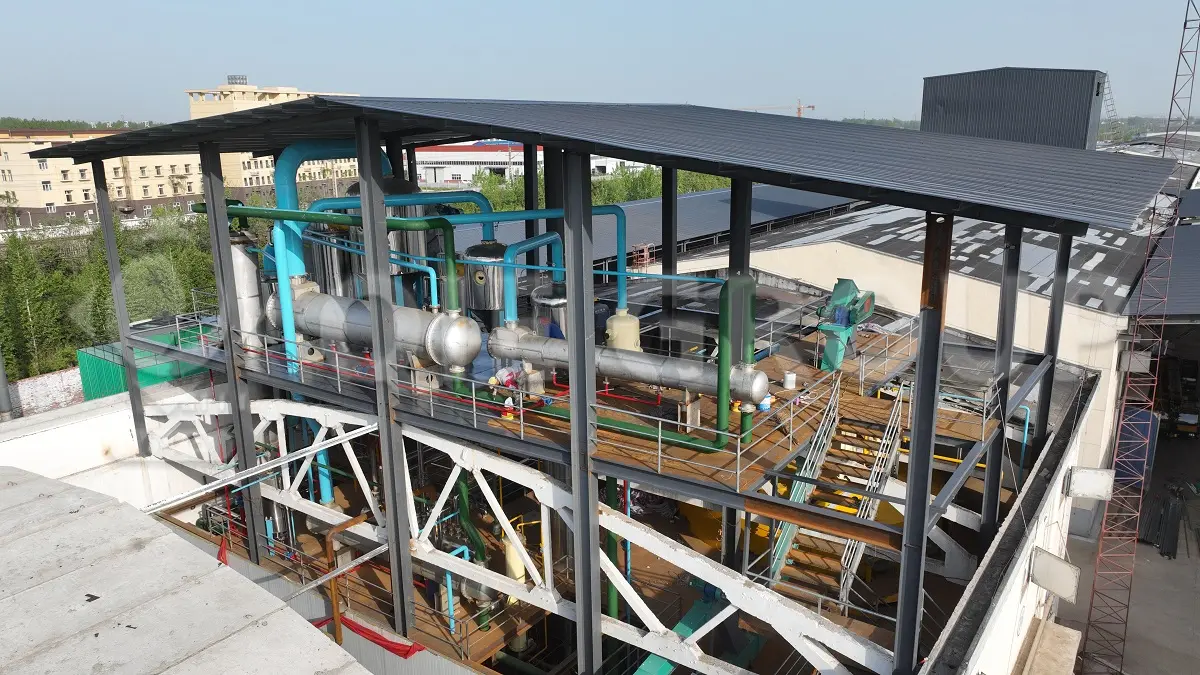

Equipment transportation and on-site installation

Electrical distribution and automation system construction

Employee operation and maintenance training

Provide long-term technical support and equipment upgrade services

African customer : 300 tons/day soybean oil production line, completed from contract signing to production in 12 months, and the products are sold well nationwide

Asian customer : After upgrading the sunflower oil processing plant, the oil yield increased by 8%, and the annual output value increased by approximately one million US dollars

1. How much investment is required to build an edible oil processing plant?

The scale of investment depends on the plant capacity, equipment selection and local infrastructure. We can provide a detailed investment budget plan.

2. What oils can be processed?

We can process a variety of oilseeds including soybeans, peanuts, cottonseeds, rapeseeds, rice bran, sunflower seeds, palm fruit, etc. We will recommend the best process based on the type of raw materials.

3. Do you provide turnkey projects?

Yes, we provide complete turnkey projects from equipment supply to installation and commissioning, training and long-term technical support to ensure smooth commissioning of your plant.

4. How is the quality of refined oil products ensured?

Through the refining process, the finished oil is transparent and pure, with low acid value and few impurities, and meets international food safety standards.

5. Is remote and long-term technical support provided?

We provide long-term remote technical support, including guidance on production anomalies, equipment maintenance recommendations, and spare parts supply services to ensure stable operation of the production line.

Choosing QIE Group will make the construction of your edible oil processing plant more worry-free, efficient and reliable .

👉 Contact our team of experts now to get a comprehensive solution and quote for your edible oil processing plant!