Rice Production & By-product Advantage: Bangladesh produces approximately 40 million tons of rice annually, generating about 4 million tons of rice bran. Currently, less than 5% of rice bran is processed into oil, leaving a large market gap.

Health Consumption Trends: Rice bran oil contains around 80% unsaturated fatty acids and natural antioxidants like vitamin E, meeting the demand of middle-class consumers for premium, healthy edible oils.

Policy Support: The government encourages value-added processing of agricultural by-products, offering tax incentives, foreign investment facilitation, and import duty reductions for equipment.

Low Raw Material Cost: Rice bran costs roughly one-third of palm oil feedstock, and processing energy consumption is lower than traditional solvent extraction methods.

High Added Value: Refined rice bran oil can be priced up to twice that of palm oil, with strong export potential to Southeast Asia and the Middle East.

Primary Source: Rice bran is a by-product of rice milling. Investors can secure a stable supply by partnering with local mills or by establishing a small rice milling operation.

Quality Control: Use fresh, mold-free rice bran, with moisture content controlled at 7–9% to prevent rancidity.

Storage: Rice bran is easy to absorb moisture and oxidize, so it needs to be stored in a dry and ventilated environment.

Foreign Investment: Foreign investors can hold controlling stakes, subject to approval by the Bangladesh Investment Development Authority (BIDA), with a minimum registered capital of USD 500,000 (check latest regulations).

Tax Incentives: Agricultural processing projects enjoy 5–7 years of tax exemption and around 30% import duty reduction on equipment (subject to official rules).

Certification: Products must comply with Bangladesh Standard BSP 101:2020 and international standards such as ISO 22000 or Codex Alimentarius.

Equipment Compliance: Recommended that processing equipment meets ISO and HACCP food safety standards.

Note: Always verify the latest policies and certifications with BIDA and food safety authorities.

Site Selection: Prefer industrial zones like Dhaka or Chittagong for stable utilities and transportation.

Workshop Design: Separate zones for pre-treatment, oil solvent extraction, and refining. Reserve approximately 20% extra space for future expansion.

Power Supply: A 30-ton/day production line requires around 500 kw, plus a backup generator due to grid instability.

Logistics Network: Partner with local logistics providers to ensure timely delivery of finished oil to major cities.

Pre-treatment: Cleaning → Crushing → Softening → Flaking → Expanding

Primary Oil Extraction (Mechanical Pressing): Screw or hydraulic presses remove part of the oil

Solvent Extraction: Residual bran is extracted to maximize oil yield

Refining: Degumming → Neutralization → Bleaching → Deodorization

Dewaxing/Winterization (Optional): Ensures high-end oil transparency

By-product Handling: Defatted bran can be used as animal feed or organic fertilizer

Pre-treatment: Cleaning sieves, crusher, flaking machine, softening machine, puffing machine

Pressing Equipment: Rice bran screw oil press machine or hydraulic oil press

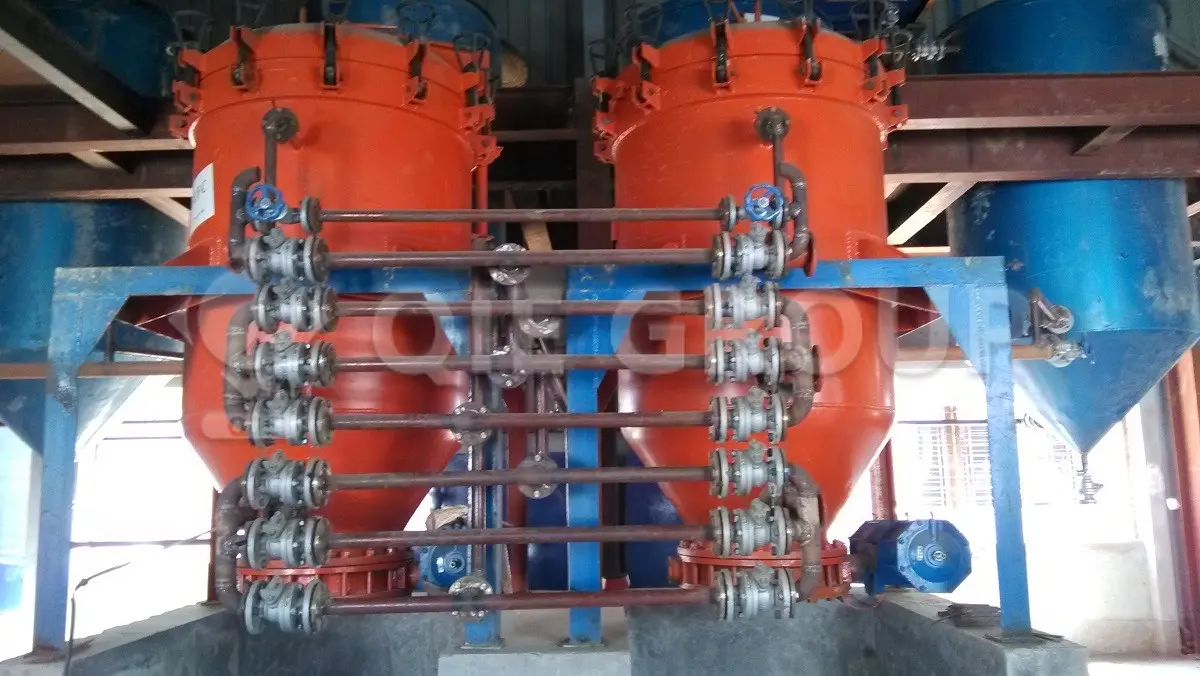

Extraction Equipment: Extractors, desolventizers, evaporators, solvent recovery systems

Refining Equipment: Refining tanks, decolorization tank, deodorizing tanks, leaf filters

Optional Dewaxing: Winterization tanks, filtration units

Using a combination of mechanical pressing and solvent extraction improves oil yield while reducing solvent usage, enhancing economic efficiency.

Key Positions: Process engineers (oil & fat specialty), maintenance technicians, quality inspectors

Training Support: Collaborate with Chinese equipment suppliers for 3 months of on-site training, including expander parameter adjustment, pressing, and solvent recovery operations.

Responsible for daily operations; require structured training to ensure safety and operational efficiency.

Covers equipment purchase, plant construction, raw material procurement, labor, and other costs

Investment varies depending on scale, ranging from hundreds of thousands to millions of USD

With proper management, profitability can be achieved within 2–3 years

ROI depends on market conditions, production efficiency, and operational management

Raw material price fluctuations

Seasonal supply instability

Energy and logistics challenges

Setting up a rice bran oil plant in Bangladesh equipped with an efficient rice bran oil production line ensures a reliable supply of high-quality oil, smooth operations, and long-term profitability.

With over 40 years of experience and global project cases, QIE Group provides turnkey solutions from single machines to complete plant installations, helping investors achieve sustainable growth in a competitive market.

👉 If you plan to invest in a rice bran oil project in Bangladesh, contact us for a customized solution!