In today’s competitive edible oil market, investors are asking: how can we build a flaxseed oil production line that ensures high oil yield while minimizing energy consumption and operational costs?Driven by the global health trend, flaxseed oil—rich in Omega-3 fatty acids and often called “liquid gold”—is experiencing growing demand across Europe, the Middle East, and Asia. To succeed in this market, only efficient, energy-saving, stable, and internationally compliant production lines can ensure your plant stands out.

With over four decades of experience, we have delivered numerous flaxseed oil production lines worldwide. From raw material pretreatment to refining and intelligent control, our solutions optimize the entire process, helping our customers seize high-end market opportunities.

Flaxseed is widely cultivated in Asia, Central Asia, Europe, and North America, ensuring a stable supply. As consumer demand for healthy oils rises, flaxseed oil is not only popular for consumption but also increasingly used in pharmaceuticals and cosmetics. Modern production lines allow investors to seize opportunities in the global vegetable oil industry.

Cleaning: Remove impurities to prevent equipment wear.

Crushing & Softening: Break down seed structure for better oil release.

Roasting/Steaming: Control temperature and moisture to enhance oil extraction efficiency.

Mechanical Pressing: Extract initial oil while preserving nutrients.

Solvent Extraction: Recover residual oil from pressed cake to maximize yield and resource utilization.

Flaxseed oil refining follows a strict sequence to ensure purity, clarity, and excellent taste:

Degumming: Remove gums and impurities to clarify the oil.

Deacidification: Reduce free fatty acids and enhance stability.

Decoloring: Adsorb pigments and unwanted substances to improve color and transparency.

Dewaxing: Remove waxes, ensuring clear, high-quality oil for premium markets.

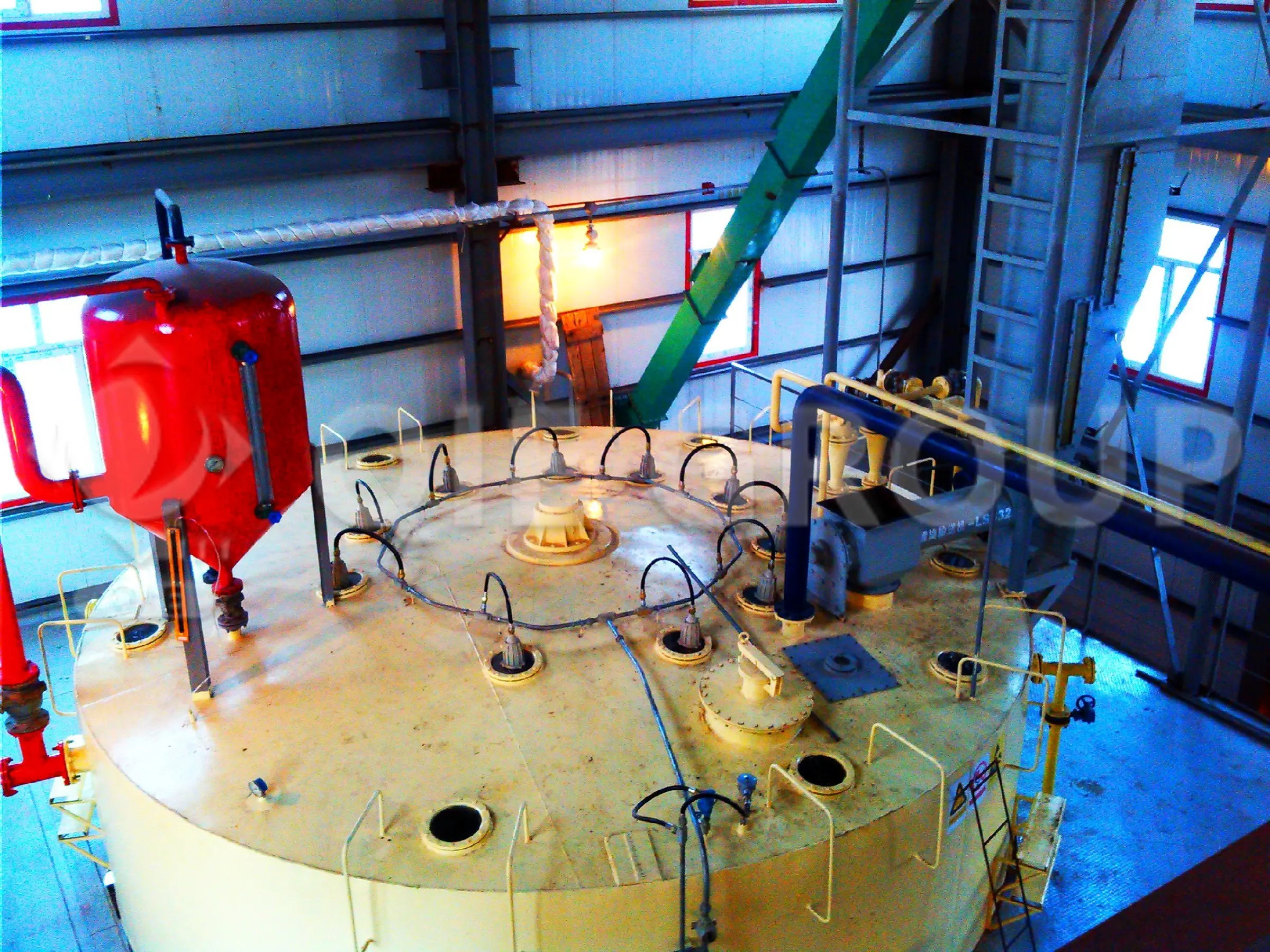

Deodorization: Use high-temperature vacuum steam to remove off-flavors while preserving Omega-3 fatty acids and other nutrients, producing oil with a clean aroma and excellent taste.

Automated control systems enable easy operation and real-time monitoring.

Energy management optimization ensures cost savings and higher overall efficiency.

Recently, QIE Group successfully delivered a 300-ton/day flaxseed oil production line in Xinjiang, operating stably and producing oil meeting export standards. Whether for medium-scale 300-ton/day projects or large-scale 100–3000 ton/day vegetable oil projects, we provide custom turnkey solutions tailored to client needs.

40+ Years of Experience: Specialized in edible oil processing equipment and engineering services.

Global Project Experience: Equipment exported to Asia, Africa, and Europe.

Full-Service Solutions: From design, manufacturing, installation, commissioning, to training, all delivered turnkey.

Energy-Saving & Environmentally Friendly: Compliant with international standards, supporting sustainable development.

Building an efficient and energy-saving flaxseed oil production line not only increases output and profits but also opens doors to high-end edible oil markets. QIE Group is committed to partnering with global clients to deliver efficient, intelligent, and sustainable vegetable oil processing solutions.