In the field of edible oil production, the crude oil squeezed out by the oil press and not processed by vegetable oil refining equipment, which we often call crude oil, contains free fatty acids, phospholipids, pigments, mucus and other substances. The presence of these substances seriously affects the quality of the oil, making it impossible for the crude oil to directly meet the standards of edible oil and must be refined with the help of vegetable oil refining equipment.

Vegetable oil refining equipment is a set of professional equipment, mainly including refining tanks, water washing tanks, vacuum dehydration tanks and filters and other key equipment. Through the coordinated operation of these equipment, various impurities in crude oil can be effectively removed and the quality of oil products can be improved.

Our company's vegetable oil refining equipment has many significant advantages. First, the equipment combination is flexible and can be customized according to the production needs of different customers. Secondly, the compact structure and small footprint greatly save plant space. In addition, the investment cost is relatively low, which reduces the threshold for enterprises or individuals to enter the edible oil refining industry. In addition, the new white mud automatic quantitative system ensures the stability and reliability of oil quality; the fully vacuum-enclosed refining process not only requires less investment, but also produces high-quality edible oil products.

Vegetable oil refining equipment is mainly used for the production and processing of edible oil. The crude oil squeezed out by the oil press is converted into refined edible oil through a series of refining processes. The refined edible oil is light yellow, clear and transparent, has no odor, and has a mellow taste. During the cooking process, no large amount of foam is generated, and there is less oil smoke, which brings consumers a better cooking experience.

So, what is crude oil? The oil produced after pressing, if it has not been processed by vegetable oil refining equipment, is called crude oil. The main component of crude oil is a mixture of glycerol and fatty acids, commonly known as neutral oil. In addition, crude oil also contains non-glycerol substances, which are collectively called impurities. According to the dispersion state of impurities in the oil, they can be roughly divided into the following four categories:

Suspended impurities: mainly solid impurities such as soil, blanks, powder, etc. The presence of these impurities provides favorable conditions for the activity of microorganisms, which can easily lead to hydrolysis and rancidity of oils and fats, making them lose their edible value.

Colloidal impurities: including phospholipids, proteins, carbohydrates, etc., among which phospholipids are the main components. These impurities not only make the oil easy to hydrolyze and become rancid, and the appearance becomes turbid and dull, but also produce a lot of foam and black precipitation during the cooking process, seriously affecting the color and flavor of stir-fried and fried foods, while reducing the nutritional value of the oil itself, and even have a certain degree of toxicity.

Oil-soluble impurities: including free fatty acids, pigments, hydrocarbon waxes, aldehydes, ketones, etc., as well as trace metals and organic phosphorus, mercury, polycyclic aromatic hydrocarbons and other harmful substances caused by environmental pollution. These impurities are extremely harmful to human health, and some impurities are even carcinogenic.

Moisture: Crude oil has a high moisture content. The presence of moisture can easily lead to oil hydrolysis and rancidity, shortening its shelf life.

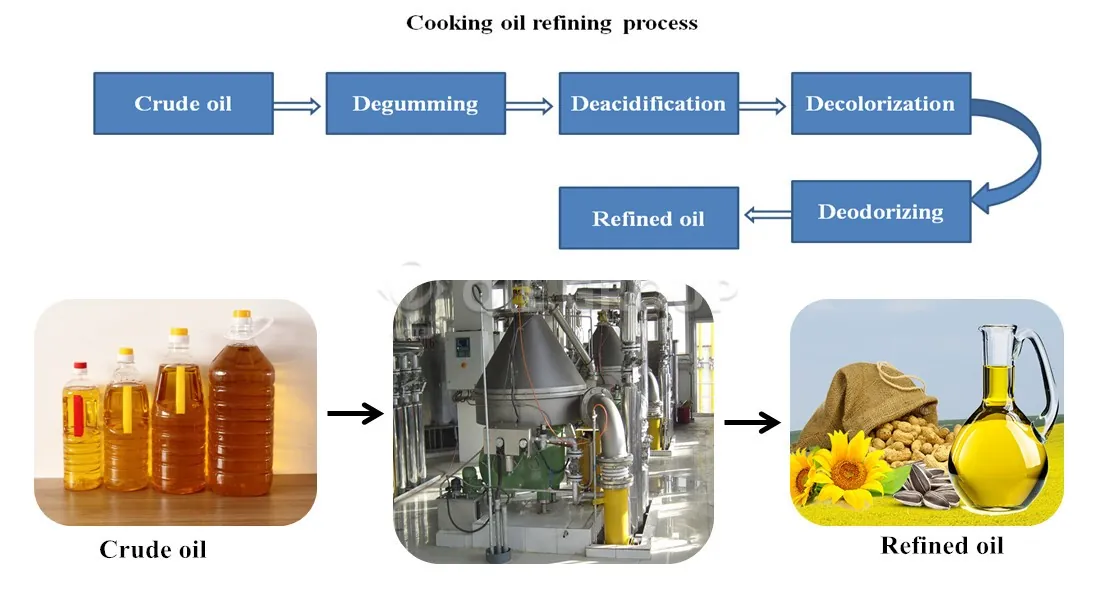

When crude oil is processed by a series of processes such as dephosphorization, deacidification, degumming, deodorization, and decolorization in vegetable oil refining equipment, impurities that are harmful to consumption and storage are effectively removed, thereby obtaining finished oil that meets national quality standards, which is what we call finished oil. Edible oil refined by vegetable oil refining equipment not only fully meets the quality standards of relevant national departments, but also has many benefits for human health.

Crude vegetable oil→alkali refining and degumming→deacidification→decolorization→deodorization→filtration→finished oil

Small investment and quick results: This equipment is suitable for users of various production and processing scales, whether it is a small workshop or a large enterprise, and can achieve a return on investment in a short time.

Small footprint and flexible operation: The equipment has a compact design, saves space, is easy to operate, and can effectively save labor costs.

Wide range of applications: Applicable to the refining of various oil products, providing more possibilities for users' business expansion.

Advanced refining technology: The refining technology that combines chemical and physical methods has greatly improved the quality of finished oil.

Modular design: Each refining stage is designed independently, which is convenient for expanding the production scale according to production needs in the later stage.

If you are interested in vegetable oil refining equipment, or want soybean oil refinery plant, cottonseed oil refining equipment, sunflower oil refining equipment, please feel free to contact us! QIE GROUP will wholeheartedly provide you with professional solutions and quality services.