Refined coconut oil is a widely used, high smoke point oil that has been processed to remove impurities, odors, and flavors. Unlike cold-pressed virgin coconut oil, refined coconut oil is bleached, deodorized, and often chemically treated to create a neutral-tasting oil suitable for high-temperature cooking and industrial applications.

Degumming is mainly to remove colloidal impurities such as phospholipids in coconut oil. Phospholipids will form micelles in oil, affecting the transparency and stability of the oil.

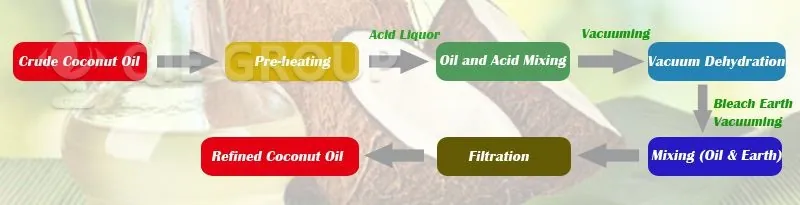

Deacidification is to remove free fatty acids from coconut oil. The presence of free fatty acids will reduce the smoke point and oxidative stability of the oil, and also affect the flavor of the oil. Chemical deacidification is to add alkali solution to the deacidification equipment to neutralize the coconut oil, thereby removing free fatty acids (FFA). Physical deacidification uses high-temperature steam and the principle of distillation to remove free fatty acids from coconut oil.

Decolorization is mainly to remove the pigment in coconut oil and improve the color of the oil. Add the decolorizer (activated clay and activated carbon) to the deacidified coconut oil, stir and adsorb it under certain temperature and vacuum conditions, so that the pigment is adsorbed by the decolorizer, and then separate the decolorizer from the oil by filtering.

Deodorization is to introduce direct steam into the oil under high temperature and high vacuum conditions so that the odorous substances are distilled out along with the steam. The odorous substances in coconut oil are removed, thereby improving the flavor and quality of coconut.

QIE GROUP has extensive experience in edible oil refining equipment. Our engineering team can customize coconut oil refining equipment of different scales according to customer needs. Please contact us.