As a healthy and nutritious edible oil, sunflower oil is deeply loved by consumers. It is rich in unsaturated fatty acids, vitamin E and other nutrients, and has many health benefits such as lowering cholesterol and anti-oxidation. So, what is the production process from plump sunflower seeds to clear and transparent sunflower oil? The following is a detailed introduction to the production steps of sunflower oil.

1. Cleaning and removing impurities: Remove stones, metals, stems and leaves and other impurities from sunflower seeds to avoid damage to equipment.

2. Shelling and separation of kernel and shell: Sunflower seed shells have a low oil content and affect the color of the oil. There may be some residual shells mixed in the shelled material, which needs to be further separated by kernel and shell separation equipment.

3. Crushing and softening: Crushing makes the sunflower seed kernels uniform in size and improves the subsequent embryo rolling effect; Softening: Regulates moisture and temperature and enhances plasticity.

4. Flaking: Press the crushed sunflower seed kernels into thin slices to destroy the cell structure of the sunflower seed kernels, making it easier for the oil to be released from the cells. At the same time, it increases the surface area of the material, which is beneficial for subsequent steaming, frying and pressing.

5. Steaming and frying (tempering): The rolled sheets are put into the steaming and frying pan. Through heating and stirring, the temperature and moisture of the sheets are brought to an appropriate range to inactivate enzyme activity and improve oil fluidity.

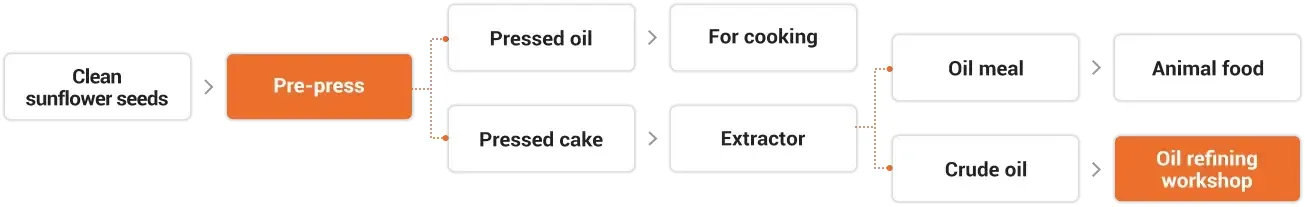

Pressing method: Pre-pressing usually uses a screw oil press machine, which applies pressure to the flakes through the rotation and propulsion of the screw shaft, so that the oil is separated from the flakes. The crude oil obtained from pre-pressing contains more impurities and needs to be refined later; the cake enters the leaching process to further extract the oil.

Solvent extraction method: pre-treated sunflower seed flakes → horizontal rotary extractor (solvent n-hexane countercurrent extraction) → mixed oil evaporation → crude oil.

1. Degumming: removal of phospholipids (hydration degumming) and peptized impurities.

2. Deacidification: Reduce free fatty acids (FFA) to prevent oil rancidity.

3. Decolorization: adsorb pigments (chlorophyll, carotenoids) to improve the color of oil products.

4. Deodorization: remove odorous substances (aldehydes, ketones) and improve oil stability.

After refining, the sunflower oil meets the standards for edible oil and needs to be filled and packaged.

Low investment, you can produce high quality sunflower oil. Are you interested in sunflower oil production line? Contact QIE GROUP now!