There are countless equipment suppliers on the market, each claiming to offer the “best technology,” making it difficult to know whom to trust.

Process design may come from a consulting institute, equipment from multiple vendors, and installation from a separate contractor—resulting in high coordination costs and blurred responsibilities.

Project budgets keep increasing, schedules slip, and after commissioning the plant still fails to meet expected capacity, energy efficiency, or oil quality targets.

When problems arise, equipment suppliers blame design, contractors blame operation, and no single party takes full responsibility.

These issues are not isolated cases. They are common outcomes of fragmented project delivery models in edible oil processing—an industry that combines mechanical engineering, chemical processing, automation, and food safety into one highly integrated system.

This is why an increasing number of experienced investors are choosing the EPC (Engineering–Procurement–Construction) contracting model. EPC is not merely a project management method; it is a risk-control and value-assurance mechanism that aligns technical responsibility with final operating results. 👉(One-stop solution for vegetable oil production line)

Edible oil processing is far more complex than purchasing an oil press and producing oil. From raw material intake to finished oil filling, a typical production line includes:

Raw material cleaning and pretreatment

Mechanical pressing or solvent extraction 👉(Solvent extraction plant for edible oil)

Crude oil refining (degumming, neutralization, decolorization, deodorization) 👉(Edible oil refining equipment)

Dewaxing or winterization (depending on oil type)

Finished oil storage and packaging

Each section's process parameters, equipment selection, and energy balance directly affect:

Oil yield

Energy consumption per ton of oil

Product quality stability

The economic value of by-products such as oil cake and soapstock

More importantly, different oilseeds—soybean, peanut, sunflower, palm, rice bran—vary significantly in oil content, cell structure, free fatty acid levels, and impurity composition. As a result, process routes and equipment configurations cannot be standardized across all oils.

Without integrated engineering experience, projects assembled from multiple independent suppliers often encounter a costly situation:

Each individual machine appears advanced, yet the overall system performs poorly.

The core value of EPC lies in placing process design, equipment integration, installation, commissioning, and performance delivery under one responsible contractor, ensuring seamless coordination and eliminating system-level inefficiencies.

Based on real project experience, clients who initially chose self-managed or split-contract models often encounter the following issues.

In one African project, a client planned to process soybeans using only screw presses. After start-up, oil yield remained below 30%—far below industry benchmarks.

The issue was not equipment quality, but an unsuitable process route. Soybeans are low-oil-content materials that require flaking, expansion, and solvent extraction to achieve oil recovery above 85%.

A single early-stage engineering decision can determine the long-term success or failure of an entire plant.

In a Southeast Asian project:

Refining vessels were supplied by Company A

Steam systems were installed by Company B

PLC automation was handled by Company C

During commissioning, deodorization temperature could not be stabilized. Each party blamed the others—steam pressure, heat transfer, or signal logic—while the plant remained idle for weeks.

While itemized procurement may seem cheaper, hidden costs often accumulate:

Design changes and rework

Interface mismatches between equipment

Extended commissioning and logistics delays

Many projects ultimately exceed the original budget by 20–30%.

Some plants are equipped with high-end individual machines yet still suffer from high energy consumption or unstable operation. Typical causes include excessive drying in pretreatment, inefficient heat recovery in refining, or automation systems designed only for basic operation rather than process optimization.

The term “turnkey project” is often overused. A truly responsible EPC contractor delivers not just installed equipment, but a fully operational and sustainable production system.

A complete EPC delivery should include the following levels:

| Delivery Level | Scope |

|---|---|

| Physical Delivery | Equipment installation, piping, electrical and control systems completed |

| Functional Delivery | Stable continuous operation at contractual capacity |

| Performance Delivery | Oil yield, energy consumption, and product quality meet agreed standards |

| Knowledge Transfer | Operators trained in operation, maintenance, and troubleshooting |

| Responsibility Delivery | Clear warranty scope, response time, and spare parts support |

As a long-term engineering-focused manufacturer and EPC service provider, QIE Group approaches projects with a single guiding question:

Will this plant operate efficiently, stably, and economically five years after commissioning?

Our EPC service framework covers four key stages.

Every project begins with in-depth analysis of:

Raw material characteristics (moisture, impurities, oil content, FFA, phospholipids)

Product positioning (standard refined oil, premium oil, cold-pressed oil, by-product utilization)

Local conditions (power supply, steam, water, climate, labor)

Investment objectives and future expansion plans 👉(Edible oil processing plant design)

Deliverables include PFDs, P&IDs, equipment specifications, plant layout, energy consumption estimates, and environmental compliance recommendations—supported by 3D modeling to minimize construction risks.

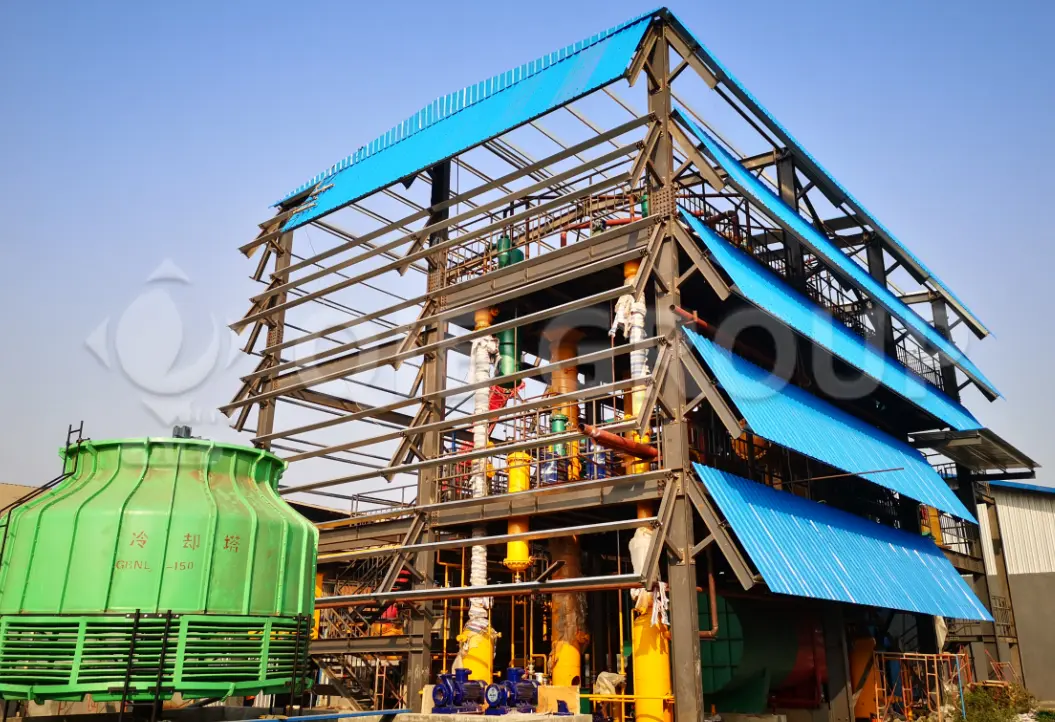

QIE Group manufactures key pretreatment, pressing, extraction, refining, and automation equipment in-house. This ensures consistency in materials, interfaces, and control logic while reducing integration risks and improving long-term service responsiveness.

Our project managers and process engineers are present on site to coordinate civil works, equipment installation, piping, electrical systems, and commissioning. Trial operation includes extended monitoring and parameter optimization—not just “start-up acceptance.”

Project delivery does not end at handover. We provide operator training, remote technical support, and global spare parts supply.

It is worth noting that EPC is not suitable for every project. For investors focused solely on minimum initial cost rather than long-term operating performance, we advise carefully evaluating whether EPC is the right approach.

In practice, EPC value is realized during long-term operation:

Lower technical risk through unified process responsibility

More predictable total investment

Shorter construction schedules through parallel engineering and manufacturing

Clear accountability with a single responsible party

For example, in high-FFA rice bran oil projects, physical refining is often recommended to minimize neutral oil loss and improve overall yield.

Proven process engineering capability beyond standard templates

In-house manufacturing of core equipment

Verified experience with similar oil types and capacities

Transparent project management and milestone acceptance

Sustainable after-sales and technical support

Q1: Is EPC suitable for small and medium edible oil plants?

A: Yes, especially when stable operation, energy efficiency, and future expansion are important.

Q2: Is EPC always more expensive than split contracting?

A: Not necessarily. While EPC may appear higher upfront, total investment and long-term operating costs are often lower.

Q3:What is the typical EPC project timeline?

A: Compared with traditional models, EPC projects are commonly completed 20–30% faster.

Q4: What performance indicators should be specified in EPC contracts?

A: Capacity, oil yield, energy consumption, product quality standards, and acceptance methods.

In EPC decision-making, the lowest bid often comes with hidden technical compromises. Designs without proven operational data can lead to permanently higher energy consumption and extended commissioning periods.

QIE Group focuses on long-term operational results—not just project completion. If you are evaluating an edible oil processing project, we can first help you assess:

Whether EPC is the right model for your project

Which sections justify higher investment

Where unnecessary costs can be avoided

Making the right decision early is often the most effective way to protect your investment.