In today's rapidly developing food processing industry, a scientific, energy-efficient, and scalable edible oil production line is a key factor determining a company's profitability and market competitiveness. Whether you are a small oil mill owner starting out for the first time or a medium-to-large producer planning to upgrade your equipment, choosing the right capacity, raw material compatibility, and automation level directly impacts oil yield, energy costs, and long-term returns.

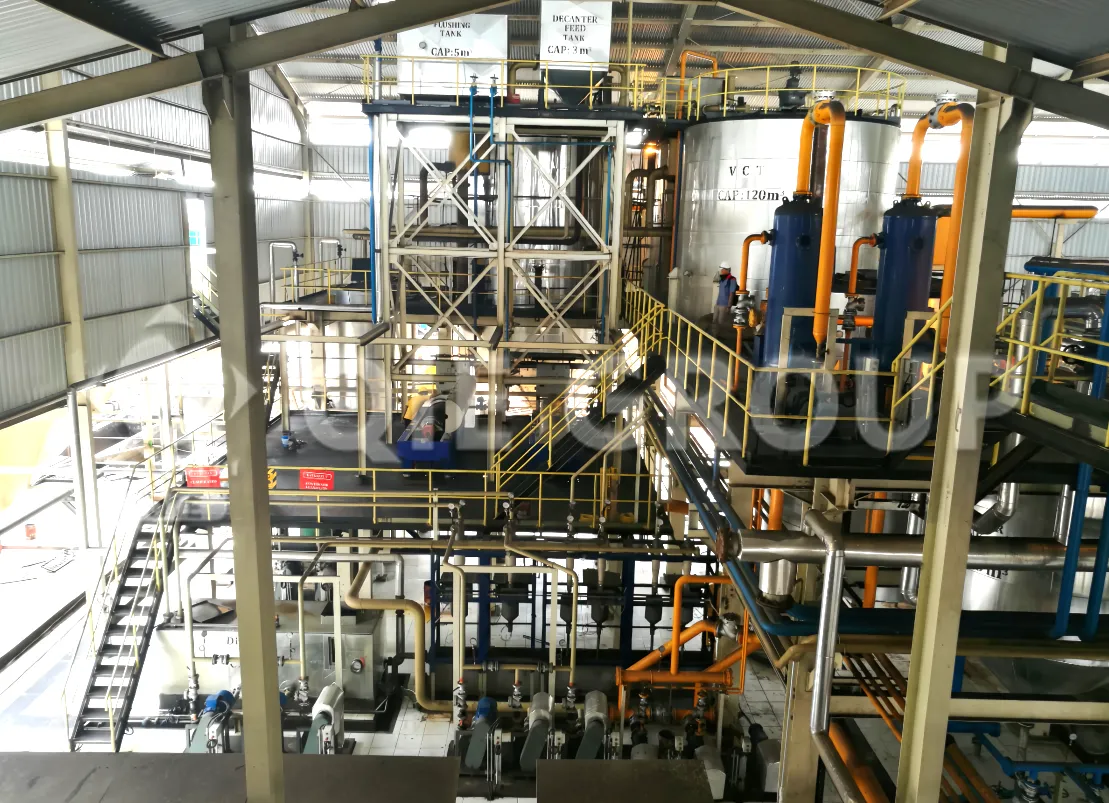

Are you struggling to choose the right capacity for your edible oil production line? Different raw material types, production scales, and investment budgets directly impact the design and economic benefits of an oil mill. QIE Group, with years of experience in oil machinery manufacturing, offers complete edible oil production lines with daily capacities ranging from 100 to 3000 tons, flexibly meeting the construction needs of oil mills of varying sizes. Whether you operate a small to medium-sized oil mill or a fully automated large-scale continuous oil processing plant, we can customize efficient and energy-saving solutions based on your investment plans and raw material characteristics.

Oil content varies significantly among different oilseeds: peanuts are about 45%, soybeans about 18%, and sunflower seeds can reach 40%. We customize the processing flow for each raw material to ensure the highest oil yield (e.g., peanuts can reach over 98%) and the lowest energy consumption.

To meet the diverse needs of our customers, we adopt a modular design concept, and our production line covers:

Raw material pretreatment system (cleaning, shelling, crushing, steaming and roasting)

Pressing systems (screw oil press, hydraulic oil press)

Solvent extraction system (rotary leaching unit, DTDC solvent removal and drying tower)

Refining system (degumming, deacidification, decolorization, deodorization)

Dewaxing and winterization system (suitable for sunflower seed oil and rice bran oil)

Filling and storage systems

💡 Each module can be scientifically matched based on production capacity, raw material characteristics, energy conditions, and budget. It supports semi-automatic or fully automatic control systems, and the production line can be easily expanded from 100 tons per day to 3,000 tons per day, maintaining high efficiency and stability.

QIE Group's edible oil production line equipment is designed with "energy saving, automation, and safety" as its core design concepts.

⚙️ Intelligent monitoring system : PLC control enables automatic data acquisition and real-time monitoring of production data;

🔧 Fault self-diagnosis function : remote troubleshooting and technical support, reducing downtime;

🔥 High -efficiency heat transfer system : Energy consumption reduced by 15%–25%, overall oil yield increased;

🌱 Environmentally friendly operation : Reduces exhaust emissions and meets environmental standards in multiple countries (ISO, CE certification).

| Process | Core equipment | Functional Description |

|---|---|---|

| Preprocessing | Cleaning machine, crusher, steamer and frying pan | Remove impurities, soften oilseeds, and improve pressing efficiency |

| press | Screw oil press, hydraulic oil press | Mechanically squeeze out crude oil with low residual oil rate |

| extraction | Rotary extractor, DTDC degassing machine, desolventizing tower | Improve oil yield and save solvent consumption |

| Refining | Degumming, deacidification, decolorization and deodorization systems | Removes impurities, pigments, and odors to improve oil purity. |

| Dewaxing | Freezing crystallization and filtration system | Improve oil clarity and storage stability |

| Filling | Measuring and packaging equipment | Realize finished oil packaging and factory inspection |

We provide not only equipment, but also systematic solutions:

🧭Preliminary consultation and feasibility analysis

🧩Process design and equipment selection

🏗️Equipment manufacturing, installation and commissioning

👨🏫Staff training and technical support

🛠️After -sales maintenance and remote diagnosis

Our goal is not just to deliver a production line, but to help you achieve higher output, lower energy consumption, and stronger market competitiveness. Whether you want to build a premium oil refinery with an annual output of tens of thousands of tons, or you want to build a highly efficient production line from scratch, QIE GROUP can tailor the most suitable development path for you.

Don't hesitate any longer, seize the opportunity to take the first step towards efficient production! Contact us for a free one-on-one assessment to help you achieve industry-leading production capabilities from day one.

Consult edible oil production line solutions now